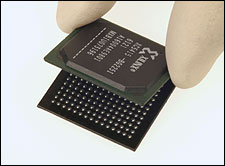

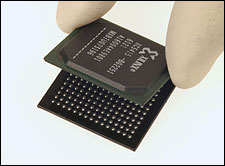

The EZReball™ reballing process allows even the beginning repair technician to reliably and quickly replace spheres on a BGA package. Alignment is simple with the edges being “squared up” with the sides of the BGA. You won’t need to buy custom fixtures or frames for your bga rework.

Since we custom make each EZReball™ perform to match your requirements, you’ll find that the solder spheres will match up to the prepped device quite easily. Once it’s reflowed, all you need to do is peel away the perform, clean it up with alcohol and your ready with the reballed device.

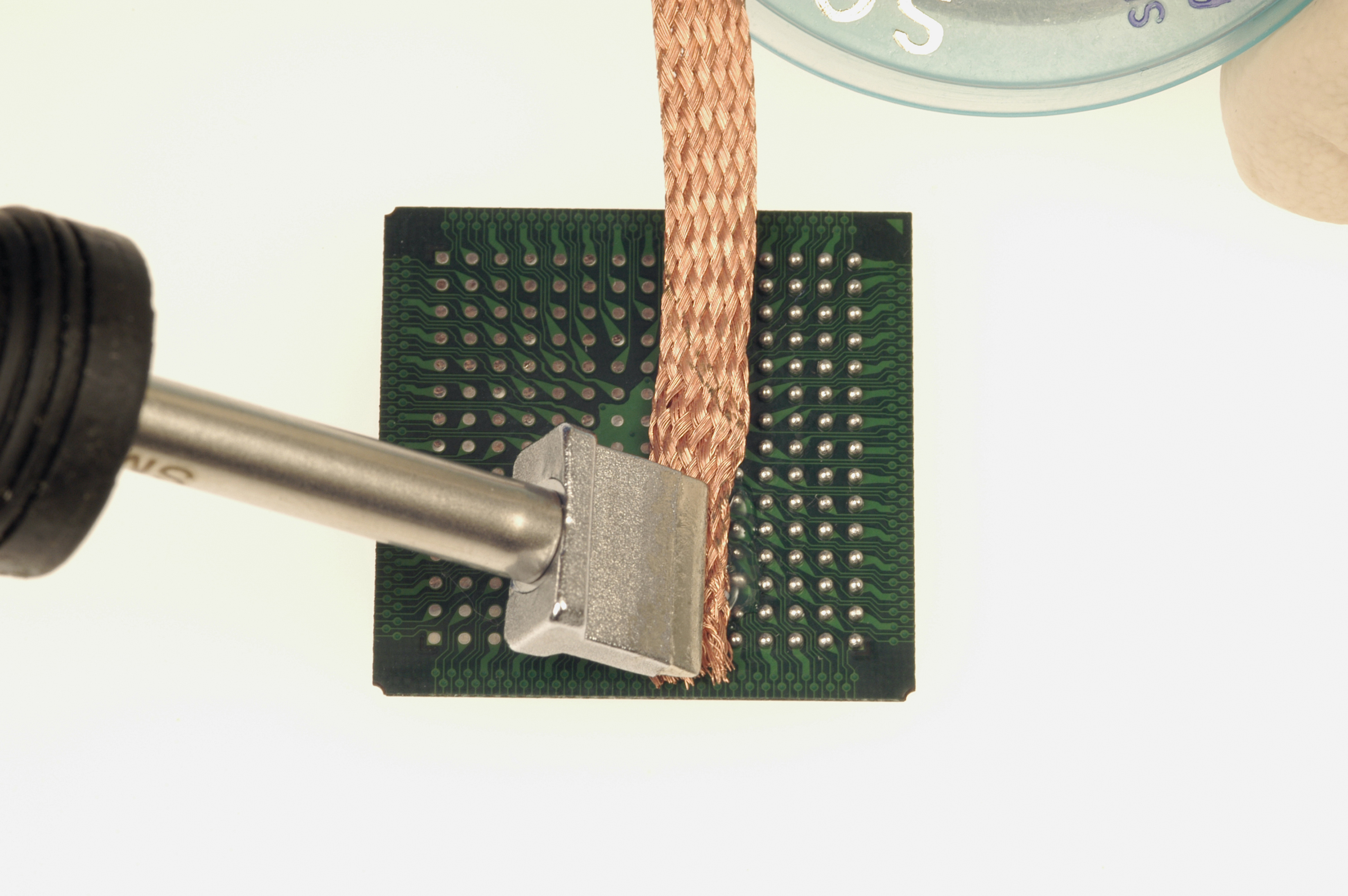

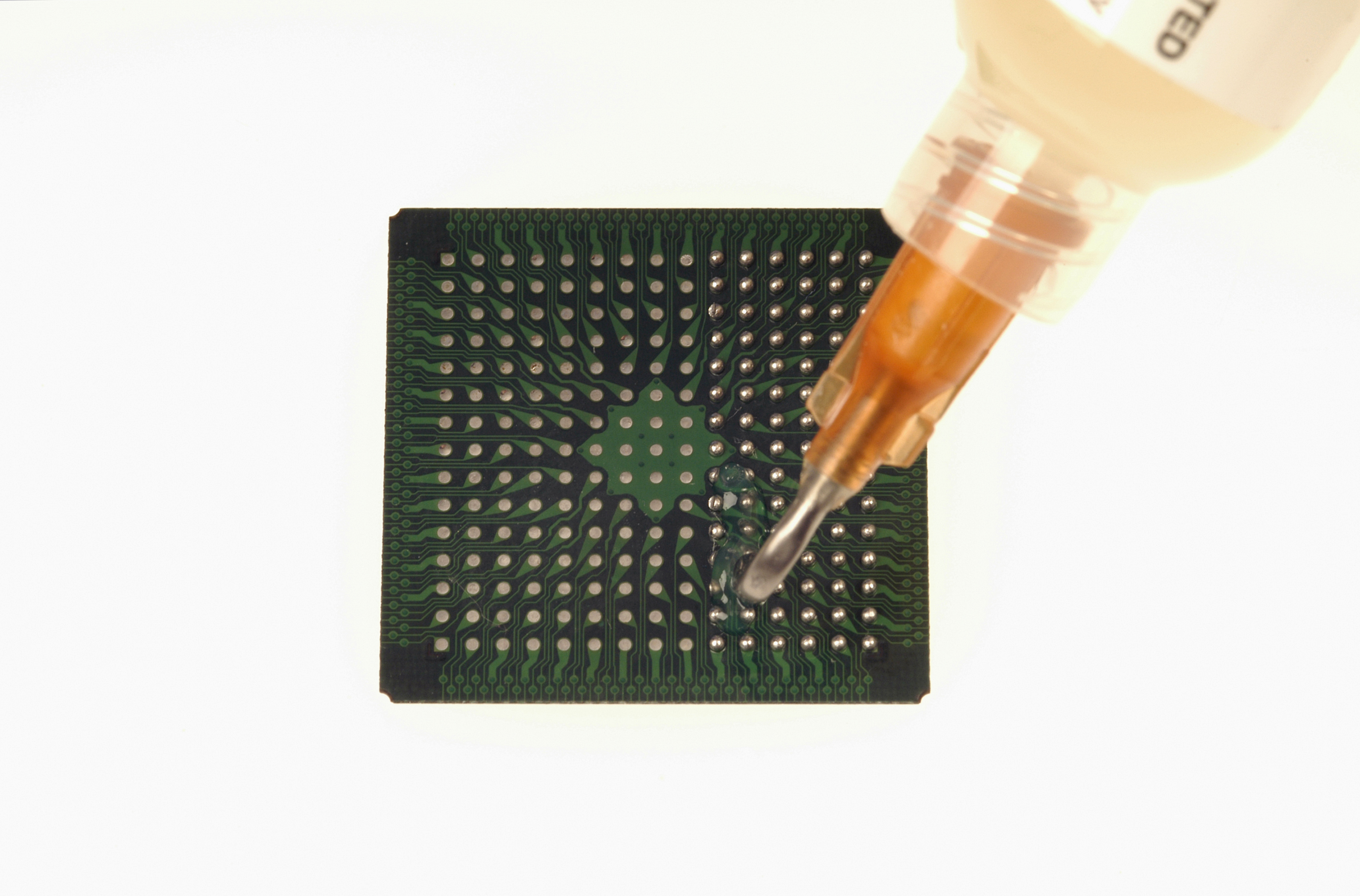

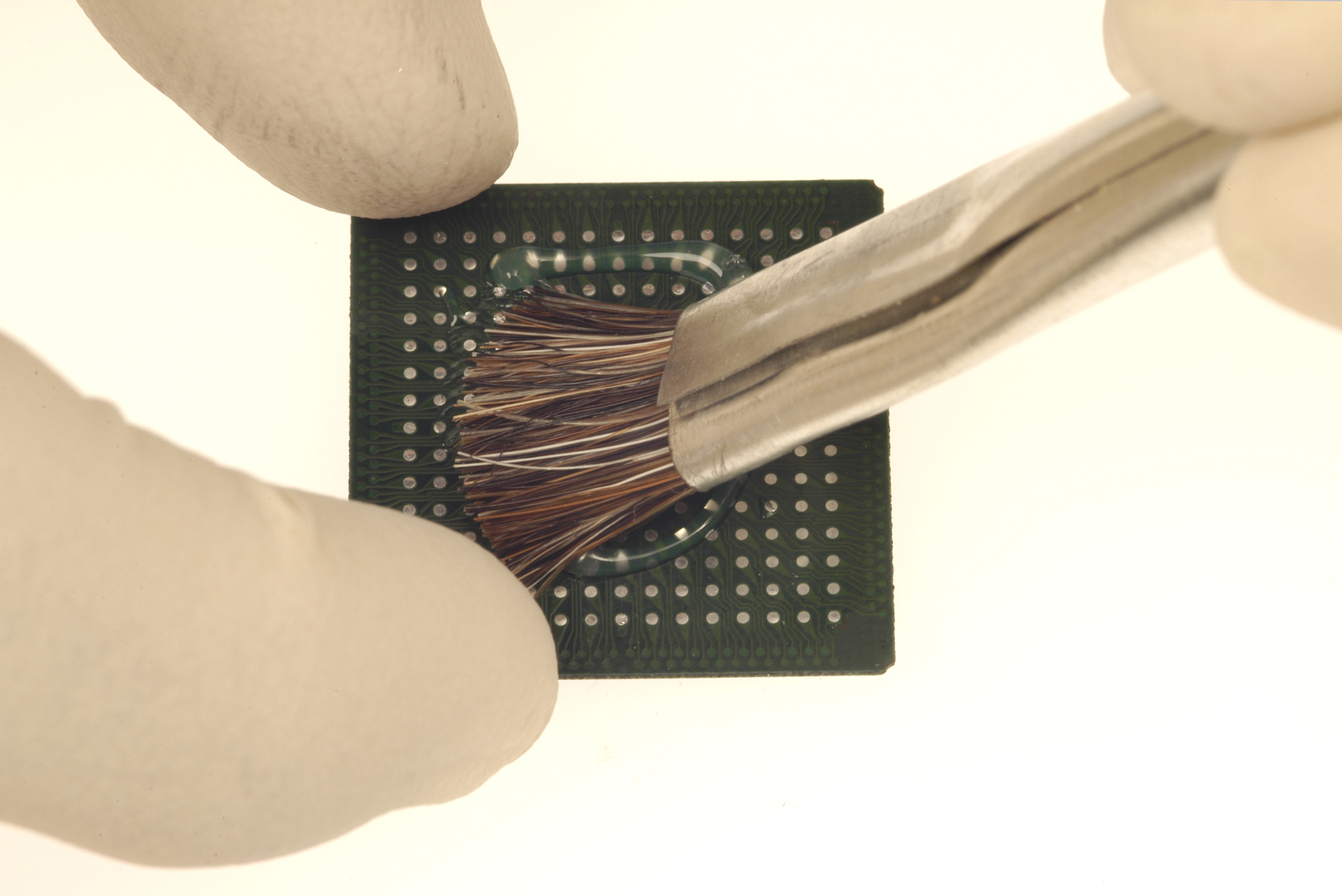

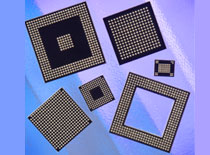

With other stencil methods using loose solder spheres, it makes it very tedious to process one component at a time. We found out through time motion studies, that if you need to reball 15 or more devices, the EZReball method is a lot faster by 30%! Speed up device reballing by following these steps

| Model | EZReball™ |

| Tensile Strength | >31,800PSI @23°C, >33,300 PSI @200°C |

| Elongation | <57% @23°C, <85% @200°C |

| Modulus | >274 KPSI @23°C, >239 KPSI @200°C |

| CTE | 20 ppm |

| TG | 351°C |

| Dimensional Stability @400°C | less than 0.40 % |

| Moisture Absorption | 4% Maximum |

| Thermal Conductivity | 0.17 W/ m K |

| UL Rating | UL 94V0 |

| Adhesive | Acrylic, thermosetting, solvent resistant |

| Standard Alloys | Melting temperature |

| Thermal Conductivity | 0.17 W/ m K |

| Sn63Pb37, Leaded | 183° C (361° F) |