What is CNC Machining?

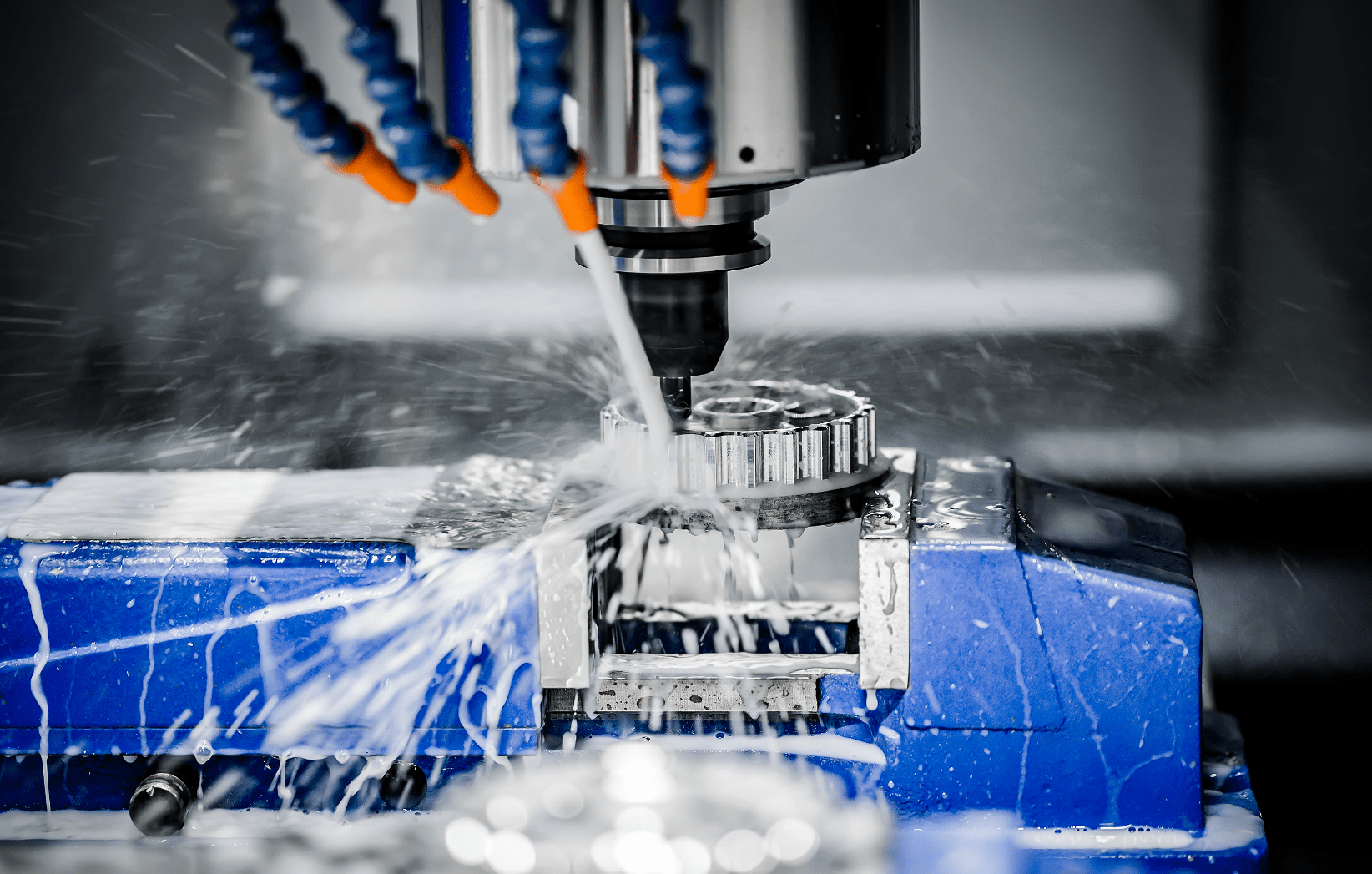

CNC (Computer Numerical Control) machining is a manufacturing process that involves the use of computer-controlled machine tools to create precise and complex parts from various materials, including aluminum, steel, plastics, and more.

CNC machining plays an important role in the manufacturing industry. It can produce parts with high accuracy and repeatability, making it a popular choice in various industries, such as aerospace, automotive, medical, and electronics.

CNC machining can involve various types of cutting tools, such as drills, mills, lathes, and routers, which are used to perform different operations, such as drilling, milling, turning, and routing.

Benefits of CNC Machining

- Precision

- Efficiency

- Versatility

- Consistency

- Flexibility

- Cost effectiveness

Properties of Aluminum Parts

Aluminum is one of the most popular used materials for CNC machining. Here are some of the key properties of aluminum parts:

| Lightweight | Although aluminum is lightweight, it is also strong and durable. Aluminum alloys can be engineered to provide excellent strength-to-weight ratios, making them suitable for applications that require high strength and stiffness, such as structural components. |

| Strength | Although aluminum is lightweight, it is also strong and durable. Aluminum alloys can be engineered to provide excellent strength-to-weight ratios, making them suitable for applications that require high strength and stiffness, such as structural components. |

| Corrosion Resistance | Aluminum forms a natural oxide layer on its surface, which provides excellent corrosion resistance. Additionally, aluminum parts can be anodized or coated to further enhance their corrosion resistance. |

| Thermal Conductivity | Aluminum has a high thermal conductivity, which means it can quickly and efficiently transfer heat. This makes aluminum parts ideal for applications that require efficient heat dissipation, such as heat sinks. |

| Electrical Conductivity | Aluminum is an excellent conductor of electricity, making it ideal for electrical applications, such as wiring and conductors. |

| Machinability | Aluminum is a relatively soft metal that is easy to machine and form. This makes it ideal for CNC machining and other manufacturing processes |

| Aesthetic Appeal | Aluminum is a versatile material that can be finished in a variety of ways, including anodizing, painting, and powder coating. This allows for a wide range of aesthetic options. |

Aluminum Alloys for CNC Machining

There are many aluminum alloys used in CNC machining, with each alloy having its own unique set of properties that make it

suitable for different applications. Here are some of the most commonly used aluminum alloys in CNC machining:

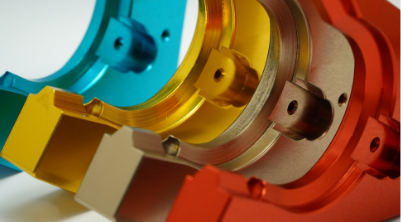

Aluminum finishes for CNC machining

There are a variety of aluminum finishes that can be applied to CNC machined parts, depending

on the desired appearance, durability, and functionality. Some common finishes include:

This is a process in which an oxide layer is grown on the surface of the aluminum. Anodizing can improve corrosion resistance, durability, and wear resistance, and can be colored in a wide range of shades.

This involves using abrasives to remove material from the surface of the aluminum, resulting in a smooth and shiny finish. Polishing can be used to achieve a mirror-like finish but may not be as durable as other finishes.

This involves applying a dry powder coating to the surface of the aluminum, which is then heated to cure the coating. Powder coating provides a durable and protective finish that can be colored in a range of shades.

This involves using abrasive pads or wire brushes to create a textured surface on the aluminum, which can give it a unique appearance and improve grip.

This involves blasting the surface of the aluminum with abrasive particles, which can create a matte or textured finish. Sandblasting can also be used to remove any surface imperfections or roughness.

Ultimately, the best finish for your CNC machined aluminum parts will depend on your specific requirements and preferences. It is always a good idea to consult with your manufacturer or finisher to determine the best finish for your needs.

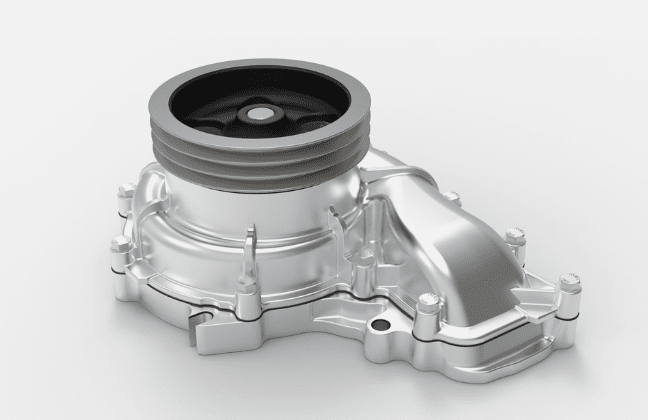

Machine Aluminum Applications

Machined aluminum parts are used in a wide range of industries and applications, thanks to their

unique combination of properties. Here are some common applications of machined aluminum parts:

Aerospace

Automotive

Electronics

Medical

Industrial

Sporting Goods

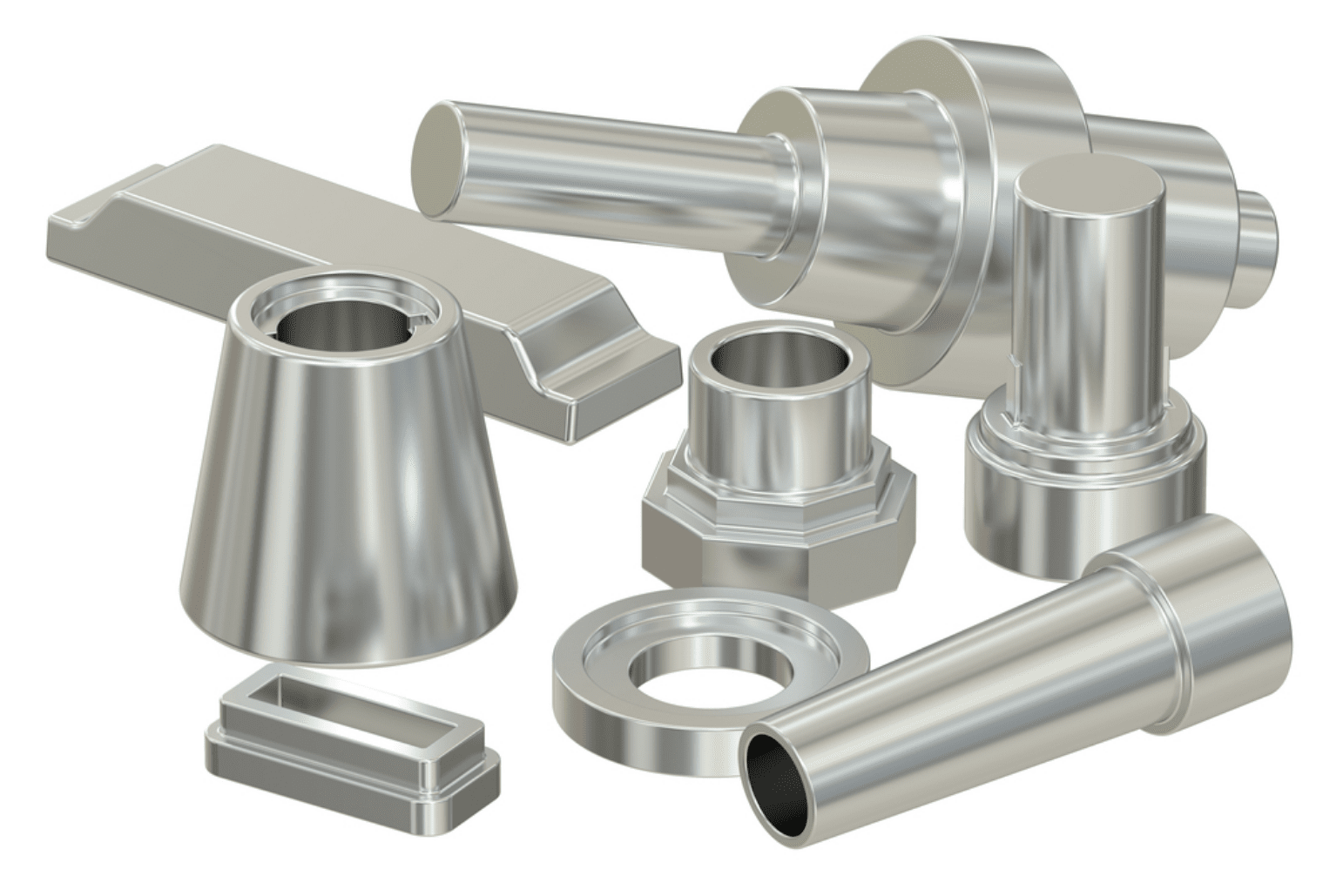

Examples of aluminum parts

Structural Components

Aluminum parts can be used as structural components in aircraft, automobiles, and other machines. Examples include engine parts, frame components, and wing spars.

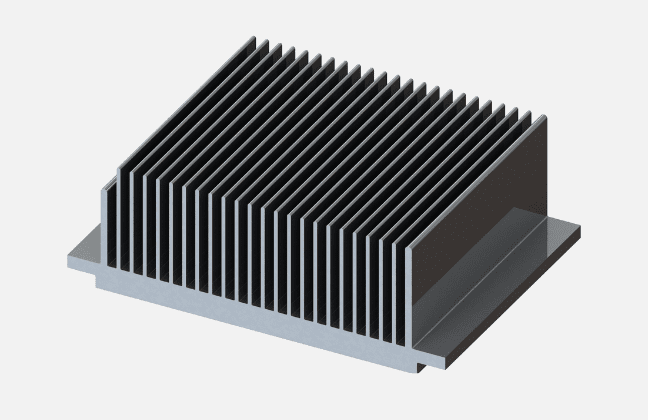

Heat Sinks

Aluminum parts can be used as heat sinks to dissipate heat from electronic devices, such as CPUs and power amplifiers.

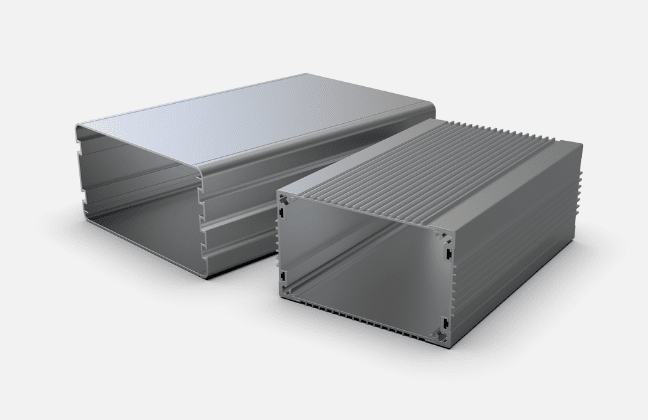

Enclosures

Aluminum parts can be used as enclosures for electronic devices and other equipment. They are often lightweight, durable, and have good electromagnetic shielding properties.

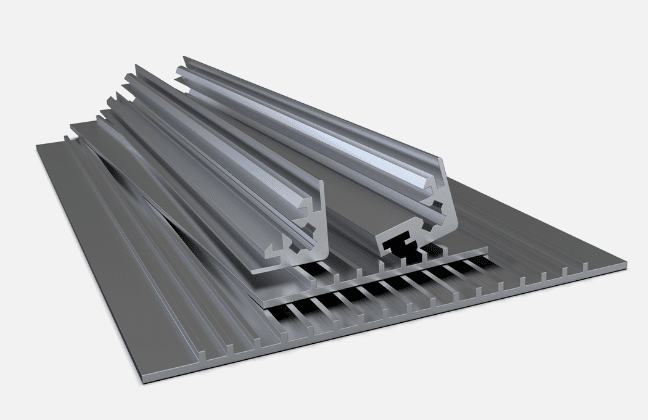

Extruded Profiles

Aluminum parts can be extruded into various shapes and profiles for use in construction and other industries. Extruded aluminum profiles are often used as frames, beams, and other structural components.

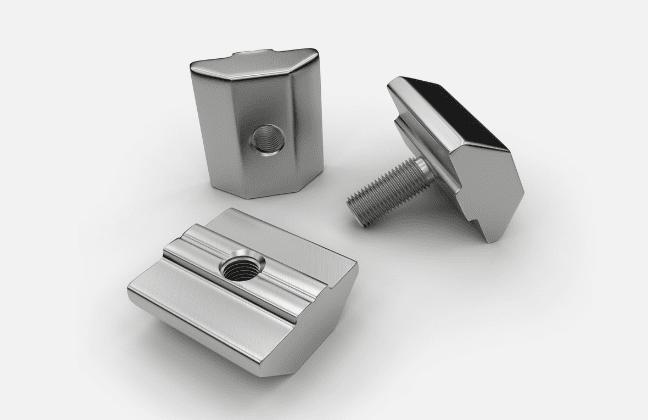

Fasteners

Aluminum parts can be used as fasteners, such as bolts, nuts, and screws, due to their lightweight and corrosion resistance properties.

Medical Components

Aluminum parts can be used in medical devices and equipment, such as surgical instruments and imaging equipment. Aluminum is biocompatible and has good corrosion resistance properties.