Stencils Unlimited specializes in precision laser manufacturing. We use advanced Infrared (IR), Ultraviolet (UV) and Carbon Dioxide (CO2) laser technology to cut thin and ultra-thin materials such as metals and plastics. We offer a variety of laser processing services as well as prototyping and micromachining with tolerances as low as +/- 2um. Please see laser technology and materials.

BENEFITS OF LASER MACHINING

Laser processing offers accurate, clean and flexible ways to develop solutions for a wide variety of materials. The laser beam can cut with high precision the most detailed features without burning or warping the surrounding areas. Here is a list of the most important benefits of precision laser cutting.

- Lower cost than traditional machining

- High precision and better repeatability from part to part.

- Perfect 90 degrees cuts.

- Cleaner surface that does not require secondary deburring

- Smooth aperture sidewalls

- No stress from physical tools

- Smaller feature sizes

- Reduced material waste

- Tighter tolerances

- Minimal heat affected areas

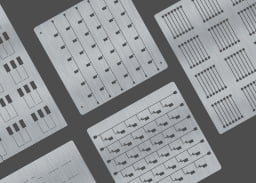

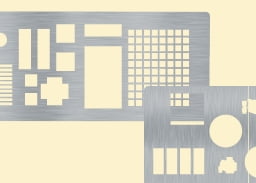

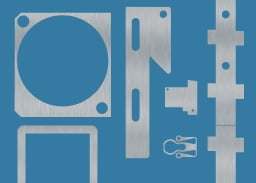

PRECISION THIN METAL PARTS

WHY STENCILS UNLIMITED FOR YOUR PRECISION

LASER MANUFACTURING PROJECTS?

- Stencils Unlimited uses a combination of state-of-the-art laser technologies including Infrared, Ultraviolet and Carbon Dioxide laser systems. This allows us to micromachine a wide variety of materials including metals, polymers, and ceramics.

- Our team of CAD engineers have extensive experience designing solutions for a variety of industries including medical, aerospace, and industrial.

- We are well known for our prototyping services. We offer competitive pricing, no minimum quantity, and fast turnaround with lead times as fast as 24 hours.

- Our customer service team is friendly and ready to help. You can contact us via email or by phone and we will be happy to answer any questions and assist you during the quoting and ordering process.

- All our precision laser cutting services are based in the USA.

LASER TECHNOLOGIES

IR LASERS

Infrared systems are typically used for to fabricate precision metal parts. Similar to a cutting torch process, the laser heats up the metal to a molten state and high-pressure air blows away the molten material leaving a smooth edge.

With the ability to focus the beam down to 25um spot sizes and the extreme accuracy of the motion systems metals up to .020" thickness can be processed with ±001" or better tolerances.

UV LASERS

Ultraviolet lasers achieve minimal heat-affected zones since it uses ablation instead of melting the material. The quick laser pulses eliminate the material so fast that the surrounding

material absorbs very little heat. This type of precision laser cutting systems are typically used in non-metal parts but also can be used on very thin metals that require ultra-fine details, a necessity for no contact cutting or special requirements for handling.

CO2 LASERS

With this technology the cutting is achieved by melting or vaporization of the material. For this process, an electric current is discharged through a gas to produce a laser. The Co2 lasers allows to process thicker metals, fired ceramics and acrylic type materials that would otherwise burn, melt or not cut with UV or IR laser systems.

| LASER TECHNOLGY | MATERIALS | ADVANTAGES | |

|---|---|---|---|

| ADVANTAGES |

|

|

|

| IR LASERS |

|

|

|

| CO2 LASERS |

|

|

|

CAD DATA

There are many forms of acceptable data. The following is a list of data formats that we accept for laser design files to be submitted in: Gerber, Gerber Extended, Excellon, DXF, DWG, HPGL, and HPGL2. Please note that it is a good idea to include a PDF drawing of the data provided for reference.

When designing a product or part that is intended for laser cutting it is important to know that quite often the primary cost driver is laser time. There are ways that you can design your data to be more efficient while cutting or for preparation before it gets to the laser. As an example, always design arcs as true arcs instead of vectors; also try to minimize the number of data points in the file when creating a design to reduce file size and increase efficiency.